Liindastering tse ling tsa tšepe tse boima, tse kang indasteri ea kaho ea likepe, mechine ea merafo le mechine ea kaho, mathata a joalo a atisa ho kopana le ona: mokhoa oa ho finyella welding e tiileng ea likarolo tsa tšepe le likarolo tsa tšepe?Hangata, likarolo tsa tšepe li tla bontša sebaka se sehiloeng ka mor'a mokhoa o akaretsang oa ho itšeha.E le ho etsa hore likarolo tsa segokanyimmediamentsi sa sebolokigolo likarolo tse welded ho feta kopantswe, ho ke ke ho hlokahala hore ho sebetsa bevels tsa libopeho tse sa tšoaneng tsa thutatekanyo ka metshetshe ya likotoana tse peli tsa tšepe, 'me joale ho phetha tjheseletsa sefahleho qetellong.Haufinyane tjena, Knoppo e phatlalalitse KP Series (matla ho tloha 30000W ho isa 8000W) Sheet.mochini oa ho itšeha oa fiber laser bevel, e tla rarolla mathata a joalo a ho cheselletsa, ho fokotsa mekhoa e boima, le ho boloka nako le litšenyehelo haholo.

Peleho itšeha ha fiber laserthekenoloji, theknoloji ea ho itšeha ea bevel e ne e boetse e sebelisoa mekhoeng ea ts'ebetso ea letlapa la tšepe joalo ka lelakabe le ho itšeha ka plasma.Leha ho le joalo, mokhoa o tloaelehileng oa ho khaola lelakabe o tla hlahisa likhahla tse tebileng, 'me bakeng sa litsela tse rarahaneng tsa li-groove, bokhoni le boemo ba ho sebetsa ba basebetsi bo hloka ho ba setsebi haholo , 'me ho tsitsa ha welding ho ke ke ha khotsofatsoa hantle;ho itšeha ka plasma Ka bophara, ho fella ka ho nepahala ha maemo a tlase, 'me likotsi tse kang mahlaseli a arc, mosi le lerata li tla hlahisoa nakong ea ts'ebetso ea ho itšeha.

Mefuta e 'meli e ka holimo ea mekhoa ea ho itšeha ke ea mokhoa o moholo oa ho kenya mohloli oa mocheso oa mocheso.Letlapa le tla senyeha ka mocheso tlas'a mokhoa oa ho sebetsa ka mocheso, 'me mokhoa o fapaneng oa deformation o hloka ho sebetsoa ka mor'a hore ho phethoe.Ha ho bapisoa le mokhoa oa setso oa beveling, laser ke mokhoa o mocha oa ts'ebetso o nang le mokelikeli o monyane ka ho fetesisa oa mocheso, boleng bo holimo ka ho fetesisa, ho nepahala ha maemo a holimo le botsitso bo botle ka ho fetisisa 'marakeng.

Letoto la Knoppo KPsheet faeba laser beveling ho itšeha mochinika haholo ntlafatsa tjheseletsa ho tiea, tjheseletsa Fusion le workpiece aesthetics ka sebetsa groove ea sebopeho itseng thutatekanyo ka ho-ho-ba-welded karolo ea weldment.Bakeng sa tšepe ea alloy, groove e ka boela ea bapala karolo ea ho lokisa karo-karolelano ea tšepe ea motheo le tšepe ea ho tlatsa.

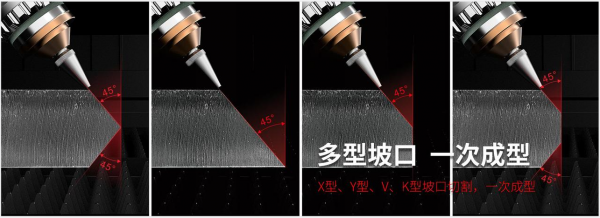

Ho ea ka botenya bo fapaneng le thepa ea 'mele ea lipoleiti tse fapaneng, khetho ea mefuta ea beveling e boetse e fapane.Mefuta e tloaelehileng ea li-beveling 'marakeng e kenyelletsa groove e bōpehileng joaloka X, groove e bōpehileng joaloka V, groove e bōpehileng joaloka Y, groove e bōpehileng joaloka K, joalo-joalo. ts'ebetso ea kamora ho tjheseletsa.Ha botenya ba tjheseletso bo ntse bo eketseha, ho sebelisoa groove e bōpehileng joaloka K kapa groove e bōpehileng joaloka X.Ka botenya bo ts'oanang, palo ea tšepe ea weld e ka fokotsoa ka hoo e ka bang 1/2, 'me ho cheseha hoa lekana,' me deformation ka mor'a welding e nyane.

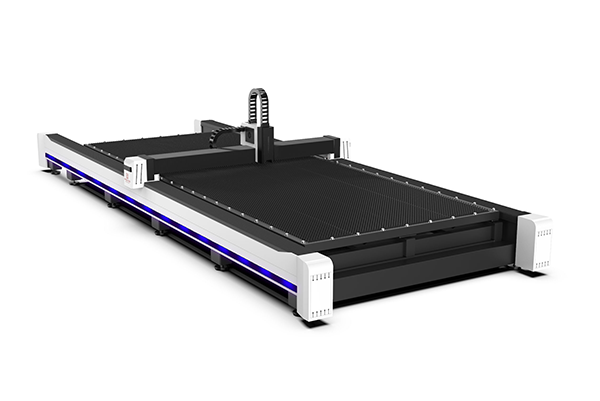

Mochini oa ho itšeha oa knoppo fiber laser beveling ke eng?

Ntlha ea pele, groove ea sebopeho se itseng sa geometri e ka sebetsoa ka ho toba karolong e lokelang ho etsoa ea weldment, e le hore seam se nang le ho kenella ka ho feletseng ha botenya bo ka fumanoa ts'ebetsong e latelang ea tjheseletsa, e le ho etsa bonnete ba. matla a ho tjheseletsa ha weldment le ho fokotsa lits'ebetso tse sa hlokahaleng., ho finyella phello e mengata;

Ea bobeli, ha ho bapisoa le ts'ebetso ea khale ea lelakabe le plasma bevel, ts'ebetso ea laser e sebetsa hantle ebile e boloka thepa.Ka mohlala, indastering ea kaho ea likepe, tšebeliso ea thekenoloji ea laser bevel cutting ho sebetsana le likarolo tse bōpehileng joaloka T tsa tšepe e tlaase ea alloy e ka boloka haholo thepa ea tšepe ea alloy ha e ntse e netefatsa botsitso ba sekepe;

Taba ea boraro, ts'ebetso ea laser e na le melemo ea deformation e nyane ea mocheso, boleng bo tsitsitseng ba ho itšeha le ho nepahala ho phahameng.Ho kopanya hantle.

Hajoale, theknoloji ea Knoppo laser bevel cutting e fihletse ts'ebetso e felletseng ea ts'ebetso ea letlapa le ts'ebetso ea profil, mme theknoloji e na le lits'ebetso tse fapaneng, tse koahelang kaho ea likepe, sehatsetsi sa indasteri, mechini ea kaho, mechini ea merafo, liphaephe tsa oli, jj.

Nako ea poso: Jul-08-2022