Ho na le mekhoa e mengata ea ho cheselletsa tšepe, joalo ka tloaelo ea argon arc welding, welding ea motlakase le mechini e meng e tloaelehileng ea welding.

Lilemong tse 'maloa tse fetileng, ho itšeha ka laser le ho tjheseletsa ka laser ho kene lebaleng la ho sebetsa le ho etsa tšepe.Bokhoni bo phahameng le boiketlo bamechine ea ho tjheseletsa laser ka letsoholi hlakile, 'me "metal welding iteration effect" e hlahisoa ka potlako, e ka batlang e nkela sebaka sa argon arc welding, welding ea motlakase le mekhoa e meng.E ka sebelisoa ka lisebelisoa tsa menyako le lifensetere, mesebetsi ea matsoho, mabone, papatso ea tšepe, kichineng ea hardware le ntloana, tableware, lisebelisoa tsa kichineng, mechine ea temo le meru, lisebelisoa tsa bongaka, lisebelisoa tsa boikoetliso ba lipapali, mechine ea kaho le liindasteri tse ling.

1. Knoppo Laser e fana ka tharollo e kopantsoeng ea ho itšeha ka tšepe, ho kobeha ha tšepe le ho cheselletsa tšepe.Ka mohlala ,mochini oa welding oa fiber laser , Mochini oa ho kobeha oa CNCle fiber laser welding machine , e ka thusang moreki ho hlahisa lihlahisoa tse ntle.

2.Motlakase oa laser o tšoaroang ka letsoho o ntlafatsa mefokolo ea welding e kang undercut, ho kena ho sa phetheheng, li-pores tse teteaneng le mapetsong a hlahang ts'ebetsong e tloaelehileng ea welding.Seam se cheselitsoeng ka mor'a hore se chesehele se boreleli ebile se setle, se fokotsang mokhoa o latelang oa ho sila le ho boloka nako le litšenyehelo.'Me ho na le lisebelisoa tse fokolang, bophelo bo bolelele,' me e ka khona ho fetoha habonolo bakeng sa libaka tse fapaneng.

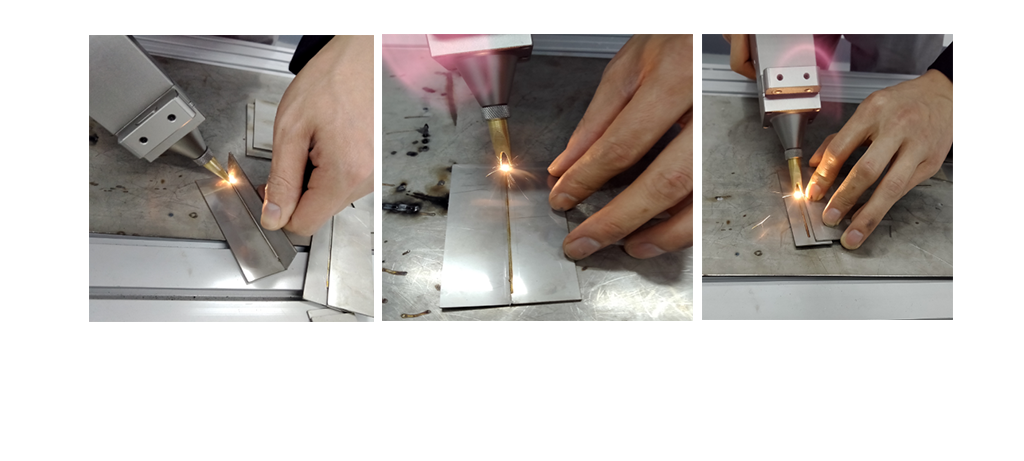

1).Beha li-parameter feela 'me u ka qala hang-hang.Ka mor'a ho nkela nozzle sebaka, ho bonolo ho etsa welding e bataletseng, angle e ka hare, angle e ka ntle, welding e fetang, joalo-joalo.

2).Beam ea laser e tšoana, ea boleng bo holimo, e tsoela pele ebile e tsitsitse, 'me e khanya ka ho lekana.The welding effect e tšoana le hore na u novice kapa letsoho le nang le tsebo.3. Ho ke ke ha e-ba le mathata a kang pores, weld bead, weld penetration, le workpiece deformation.

3).Bakeng sa lisebelisoa tsa tšepe tse kang tšepe e sa hloekang, lakane e nang le galvanized, poleiti e batang, joalo-joalo, ha e le hantle e ka lemoha nako e le 'ngoe e potlakileng ea ho cheselletsa, e leng makhetlo a' maloa ka potlako ho feta mekhoa e meng ea ho tjheseletsa.

3.Knoppo Handheld Laser Welding Machineke thepa e ncha e nkang sebaka sa tjheseletsa ea setso.E na le lebelo le potlakileng la tjheseletsa, e leng hoo e ka bang ka makhetlo a 5-10 ka potlako ho feta tjheseletsa ea setso.Thepa e bonolo ho sebetsa, 'me katleho ea welding e phahame.Mochini o le mong o ka boloka bonyane li-welders tse 2 selemo se seng le se seng, 'me laser e na le bophelo bo bolelele ba ts'ebeletso (lihora tse fetang 100,000).E ka fokotsa haholo litšenyehelo tsa lisebelisoa le litšenyehelo tsa basebetsi.

4. Melemo ea mochini oa welding oa Knoppo fiber laser :

1).E bonolo, e bonolo ho ithuta, e tenyetseha ebile e bonolo.Ho amohela sebopeho se kopantsoeng, mosebeletsi ha a hloke, koetliso e bonolo e ka sebelisoa, ts'ebetso e bonolo, e potlakileng ho qala;multi-dimensional welding, tenyetsehang le bonolo;

2).Theko e tlase ea ho kenya le litšenyehelo tsa tlhokomelo.Ho tjheseletsa laser ka letsoho, ha ho hlokahale hore ho be le tafole e ntle ya ho tjheseletsa, disebediswa tse fokolang, ditjeho tse tlase tsa ho tsamaisa thepa le ho di lokisa, le tshebetso ya ditjeho tse phahameng;

3).Pholosa mosebetsi.Ho tjheseletsa laser ka letsoho ho potlakile, ka makhetlo a 5-10 ho feta ho tjheseletsa ha setso, mme mochini o le mong o ka boloka bonyane li-welders tse 2 ka selemo;seam weld ka mor'a hore tjheseletsa e boreleli ebile e ntle, e fokotsa mokhoa o latelang oa ho belisa, ho boloka nako le litšenyehelo;

4).Boleng bo botle.Laser welding workpiece ha e na deformation, ha ho lebali tjheseletsa, 'me tjheseletsa e tiile;

5).Tšireletso ea tšireletso.E na le ts'ebetso ea ts'ireletso ea mofuta oa ho ikopanya ho qoba ho ntšoa ha leseli ka phoso le ho netefatsa hore leseli le ka ts'oaroa feela kamora ho kopana le tšepe.E na le likhalase tsa laser tse sireletsang, tse lokelang ho apesoa ha li cheselletsa.Ho netefatsa polokeho.

Nako ea poso: Dec-15-2021