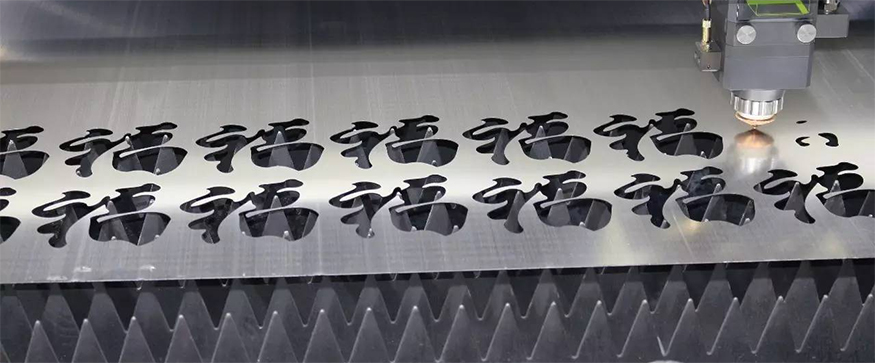

1. Ho itšeha ka mokhoa o phahameng ka ho fetisisa: laser cutting machine positioning ho nepahala ha 0.05mm, pheta ho nepahala ha boemo ba 0,03 mm.

2. Laser ho itšeha mochini moqotetsane kerf: ho lebisa tlhokomelo ea laser beam sebakeng se senyenyane, ntlha tsepamiso ho finyella phahameng segokanyipalo sa matla, thepa e ka potlako halefile ho vaporization tekanyo e ile ea fetoha mouoane ho theha masoba.Ka phala le thepa e batlang e lekana, e le hore masoba a tsoele pele ho thehoa ka lekhalo le moqotetsane, bophara ba bophara ke 0.10-0.20mm ka kakaretso.

3. Laser ho itšeha mochini boreleli seha holim'a: ha ho burr seha holim'a metsi, seha holim roughness tsa taolo kakaretso ka hare ho Ra6.5.

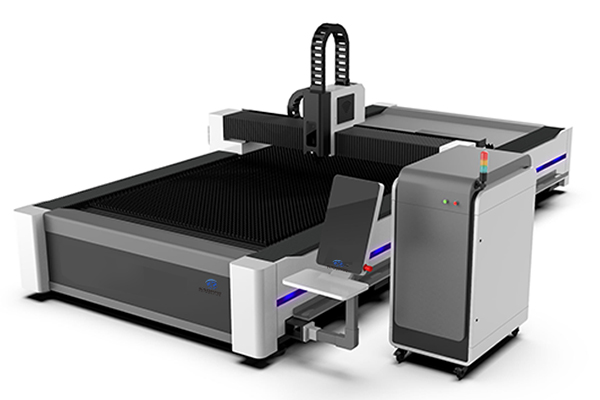

4. Lebelo la mochine oa ho itšeha Laser: lebelo la ho itšeha ho fihlela ho 10m / min Lebelo le phahameng la ho beha maemo ho fihlela ho 30m / min le potlakile ho feta lebelo la mohala oa ho itšeha.

5. Mochini o motle oa ho itšeha oa laser: sag e sa amaneng le ho itšeha, mocheso oa ho kuta o na le phello e fokolang, ha e le hantle ha ho na deformation ea mocheso oa workpiece, ho qoba ka ho feletseng lintho tse entsoeng ha li phunya, ho petsoha ka kakaretso ha ho hloke ts'ebetso ea bobeli.

6. U se ke ua senya workpiece: hlooho ea laser ho itšeha ha e kopane le holim'a thepa ho etsa bonnete ba hore u se ke ua senya workpiece.

7. Ha e amehe ke sebopeho sa workpiece: laser processing flexible, 'me e ka sebetsana le litšoantšo leha e le life, e ka khaola liphaephe le litlaleho tse ling.

8. Mochini oa ho itšeha oa laser o ka khaola mefuta e sa tšoaneng ea lisebelisoa: tse kang polasetiki, lehong, letlalo la PVC, masela, khalase le tse ling tse joalo.

9. Ho boloka hlobo ea matsete: ts'ebetso ea laser ntle le hlobo, ha ho na hlobo e sebelisoang, eseng ho lokisoa ha hlobo, nako ea ho boloka hlobo, ho boloka litšenyehelo tsa ts'ebetso, ho fokotsa litšenyehelo tsa tlhahiso, haholo-holo bakeng sa machining lihlahisoa tse kholo.

10. Ho boloka boitsebiso: mananeo a k'homphieutha, a ka khaoloa ka libopeho tse fapaneng, ho eketsa tšebeliso ea thepa.

11. Eketsa lebelo la fektheri ea sampuli: ka mor'a ho thehoa ha litšoantšo tsa lihlahisoa, ts'ebetso ea laser e ka etsoa hang-hang, fumana mofuta oa lihlahisoa tse ncha ka nako e khutšoanyane ka ho fetisisa.

12. Tšireletseho le ts'ireletso ea tikoloho: litšila tse sebetsanang le laser, lerata le tlaase, le hloekileng, le sireletsehileng, le se nang tšilafalo, le ntlafatsa haholo tikoloho ea mosebetsi.

Nako ea poso: Jan-04-2021